Description

Product Overview

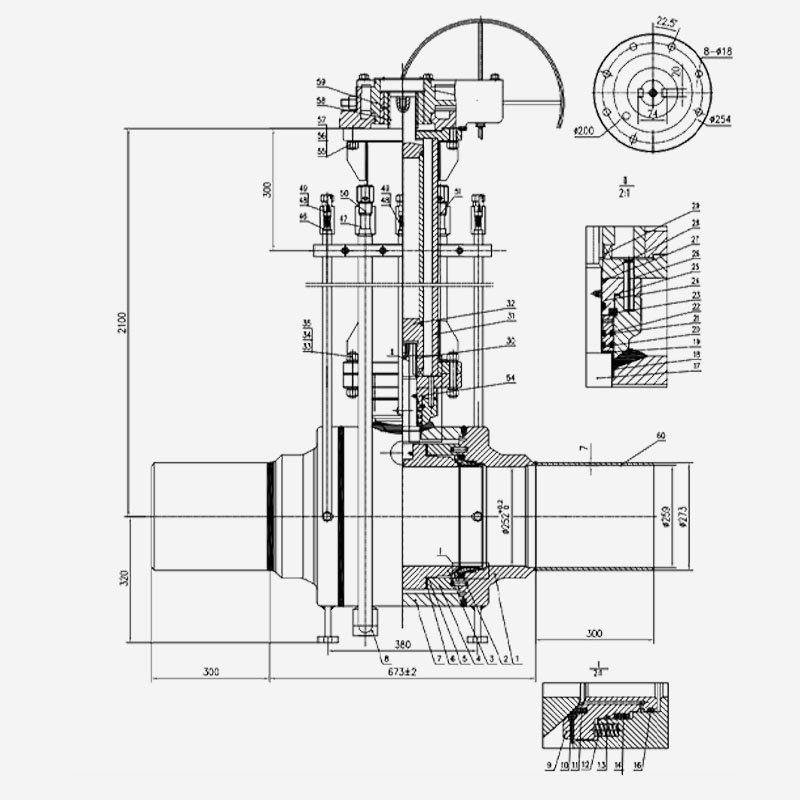

Fully Welded Heating Ball Valve is widely used as an on-off control device in urban heating systems, heat and power pipe networks for water and steam supply, petrochemicals, petroleum, natural gas, pharmaceuticals, and other fields. The valve body is made of high-strength carbon steel seamless pipes or steel plates, which are pressed and formed into a fully welded structure. The ball can be either a floating or fixed structure. The sealing structure of the valve seat is designed as a multi-stage sealing structure with a single or double soft-sealing ring, ensuring reliable sealing and long-term stable operation of this series of ball valves.

Structural Features

- The valve stem is made of high-performance stainless steel material with good corrosion resistance. The sealing materials are fluororubber (FPM) and carbonized tetrafluoroethylene (PTFE+C), which are characterized by high strength, high temperature and high pressure resistance, and corrosion resistance. The valve body material uses the same high-strength carbon steel as the pipeline, which will not experience uneven stress, nor will it deform due to earthquakes or passing vehicles. The pipeline is resistant to aging and can also be connected with flanges or other methods according to customer needs.

- The ball is made of high-performance stainless steel and the entire manufacturing process is tracked and tested by advanced computer detectors, so the machining precision of the ball is very high, making the operation easy and without interference.

- The valve stem is designed to be explosion-proof for safe usage.

- The entire assembly process of the valve is completed at a constant temperature, ensuring product quality.

- Compared with similar products in the same industry, the valve body design is compact and aesthetically pleasing.

- With normal operation and usage of the valve, the service life can reach more than 20 years.